How Space Elevators Will Work

When the Space Shuttle Columbia lifted off on April 12, 1981, from Kennedy Space Center, Fla., to begin the first space shuttle mission, the dream of a reusable spacecraft was realized. Since then, NASA has launched more than 100 missions, but the price tag of space missions has changed little. Whether it is the space shuttle or the non-reusable Russian spacecraft, the cost of a launch is approximately $10,000 per pound ($22,000 per kg).

A new space transportation system being developed could make travel to Geostationary Earth Orbit (GEO) a daily event and transform the global economy.

A space elevator made of a carbon nanotubes composite ribbon anchored to an offshore sea platform would stretch to a small counterweight approximately 62,000 miles (100,000 km) into space. Mechanical lifters attached to the ribbon would then climb the ribbon, carrying cargo and humans into space, at a price of only about $100 to $400 per pound ($220 to $880 per kg).

In this article, we’ll take a look at how the idea of a space elevator is moving out of science fiction and into reality.

To better understand the concept of a space elevator, think of the game tetherball in which a rope is attached at one end to a pole and at the other to a ball. In this analogy, the rope is the carbon nanotubes composite ribbon, the pole is the Earth and the ball is the counterweight. Now, imagine the ball is placed in perpetual spin around the pole, so fast that it keeps the rope taut. This is the general idea of the space elevator. The counterweight spins around the Earth, keeping the cable straight and allowing the robotic lifters to ride up and down the ribbon.

Under the design proposed by LiftPort, the space elevator would be approximately 62,000 miles (100,000 km) high. LiftPort is one of several companies developing plans for a space elevator or components of it. Teams from across the world are set to compete for the $400,000 first prize in the Space Elevator Games at the X Prize Cup in October 2006 in Las Cruces, New Mexico.

The centerpiece of the elevator will be the carbon nanotubes composite ribbon that is just a few centimeters wide and nearly as thin as a piece of paper. Carbon nanotubes, discovered in 1991, are what make scientists believe that the space elevator could be built. According to Dr. Bradley Edwards of the Spaceward Foundation, “Previously the material challenges were too great. But now we’re getting close with the advances in creating carbon nanotubes and in building machines that can spin out the great lengths of material needed to create a ribbon that will stretch up into space” [ref].

Under some early plans, leftover construction materials will be used to form the counterweight.

Under some early plans, leftover construction materials will be used to form the counterweight.

PHOTO COURTESY LIFTPORT GROUP

Carbon nanotubes have the potential to be 100 times stronger than steel and are as flexible as plastic. The strength of carbon nanotubes comes from their unique structure, which resembles soccer balls. Once scientists are able to make fibers from carbon nanotubes, it will be possible to create threads that will form the ribbon for the space elevator. Previously available materials were either too weak or inflexible to form the ribbon and would have been easily broken.

“They have very high elastic modulus and their tensile strength is really high, and that all points to a material that, in theory, should make a space elevator relatively easy to build,” said Tom Nugent, research director, LiftPort Group.

A ribbon could be built in two ways:

Long carbon nanotubes — several meters long or longer — would be braided into a structure resembling a rope. As of 2005, the longest nanotubes are still only a few centimeters long.

Shorter nanotubes could be placed in a polymer matrix. Current polymers do not bind well to carbon nanotubes, which results in the matrix being pulled away from the nanotubes when placed under tension.

Once a long ribbon of nanotubes is created, it would be wound into a spool that would be launched into orbit. When the spacecraft carrying the spool reaches a certain altitude, perhaps Low Earth Orbit, it would begin unspooling, lowering the ribbon back to Earth. At the same time, the spool would continue moving to a higher altitude. When the ribbon is lowered into Earth’s atmosphere, it would be caught and then lowered and anchored to a mobile platform in the ocean.

The ribbon would serve as the tracks of a sort of railroad into space. Mechanical lifters would then be used to climb the ribbon to space.

Creators of mankind

Creators of mankind Description of “Tall white aliens”

Description of “Tall white aliens” Where they came from?

Where they came from? About hostile civilizations

About hostile civilizations The war for the Earth

The war for the Earth “Tall white aliens” about eternal life

“Tall white aliens” about eternal life Video: “Nordic aliens”

Video: “Nordic aliens” Aliens

Aliens Alien encounters

Alien encounters The aliens base

The aliens base UFO

UFO Technology UFO

Technology UFO Underground civilization

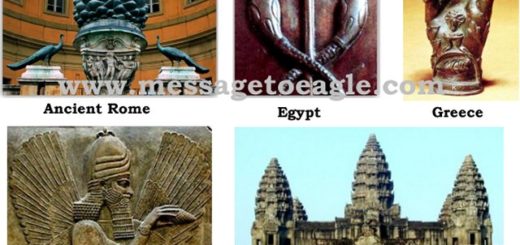

Underground civilization Ancient alien artifacts

Ancient alien artifacts Military and UFO

Military and UFO Mysteries and hypotheses

Mysteries and hypotheses Scientific facts

Scientific facts